Why Choose Us

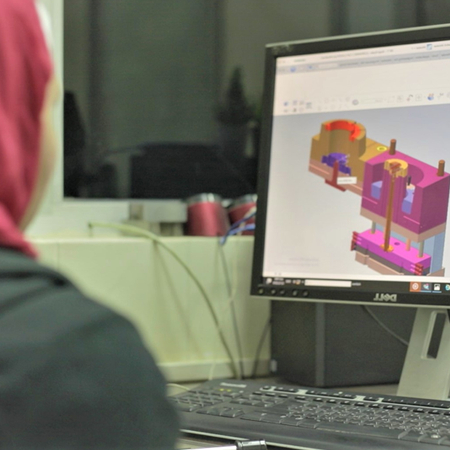

Talent Designers for Mold Design

-Over 25 Years of Technology Accumulation

-Over 20 Years Experiences Export Molds

-Creative Design Thinking

-Fluent English Technical Team

-Extremely Fast Response Speed

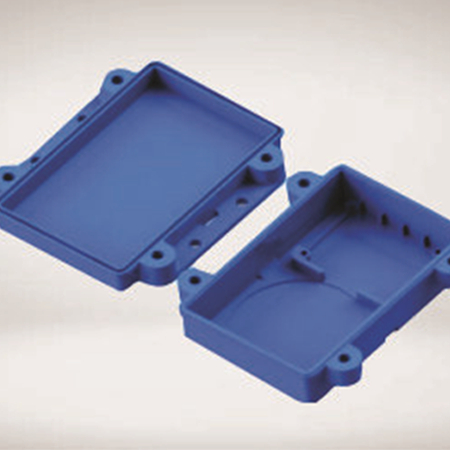

Prototyping: 3D Printing

prototype is made to represent the desired finished part from the material to the mechanics. Functional prototypes allow you to test your product design before moving on to the production phase. These are the prototypes we specialize in at the Engineering Resource Center.

3D printing is a great way to get a visual prototype. 3D printing is a cheap way to create plastic parts but is not a replacement for injection molding. Injection molding is the only way to manufacture a functional, working plastic prototype.

ELSAFA PLAST MOLD FACTORY

ELSAFA PLAST MOLD FACTORY offers a unique combination of decades of mold design

experience with the latest CAD technologies.

We currently employ 10designers, most of whom have actual tool shop experience.

This experience gives our designers a “real world” concept of mold making and the information necessary for quality designs.

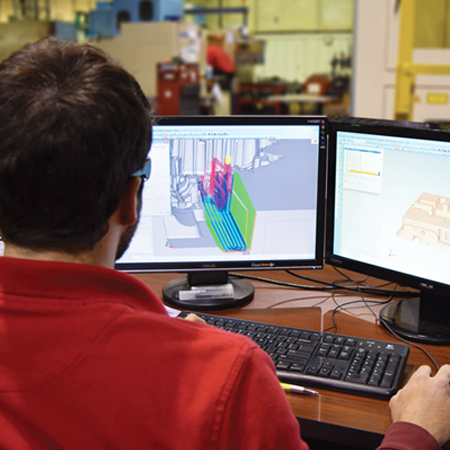

Mold flow Analysis

Mold Flow provides simulation tools for injection mold design. By iterating molding simulations, our team can optimize product designs, mold designs, and prevent multiple modifications to the mold, reducing costs and time. The Mold Flow Analysis include:

Plastic material analysis

Wall thickness analysis.

Feed system analysis.

Processing conditions.

Filling process.

Filling time.

The pressure at V/P switchover.

The temperature at the flow front.

Sink marks estimate.

Average volumetric shrinkage

Weld lines.

Defection—X, Y, Z—direction

Air traps.

Injection Pressure & Clamp. force Summary.

Bottles

Bottles